It is common, if not mandatory, for tube manufacturers to use some form of non-destructive testing (NDT) during tube production. Two different methods are typically used: Eddy Current Testing (ECT) and Ultrasonic Testing (UT) have their own advantages and limitations, depending on specific criteria such as flaw type, flaw size, or inspection speed. When it comes to tube production, one element is paramount: very high throughput speeds are essential to maximize profitability.

Details

It is common, if not mandatory, for tube manufacturers to use some form of non-destructive testing (NDT) during tube production.

Two different methods are typically used: Eddy Current Testing (ECT) and Ultrasonic Testing (UT) have their own advantages and limitations, depending on specific criteria such as flaw type, flaw size, or inspection speed. When it comes to tube production, one element is paramount: very high throughput speeds are essential to maximize profitability.

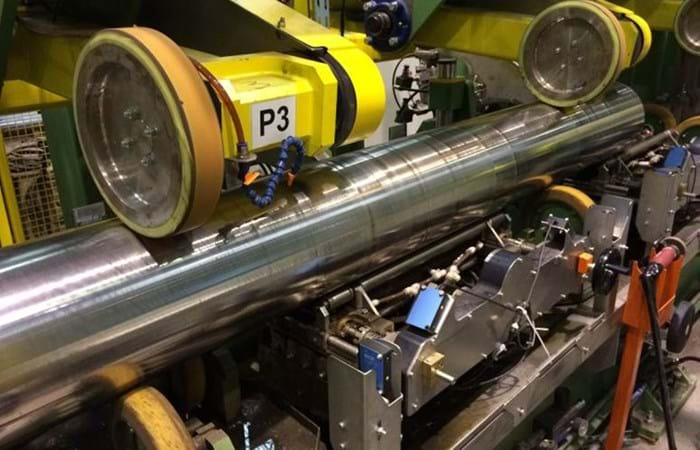

UT is typically used to find relatively long, continuous defects such as incomplete seam welds. However, it is possible to use an advanced form of UT called Phased Array UT (PAUT) to find smaller defects. For example, Eddyfi Technologies’ Panther product range combines the speed and performance of PAUT technology and Total Focusing Method (TFM) to offer unparalleled performance. To reduce cycle time and increase production capabilities, the M2M Panther is designed with tremendous processing power and the highest data transfer rate on the market. Targeted towards integrators for inline inspections and laboratories for R&D, Panther products offer a flexible and scalable solution.

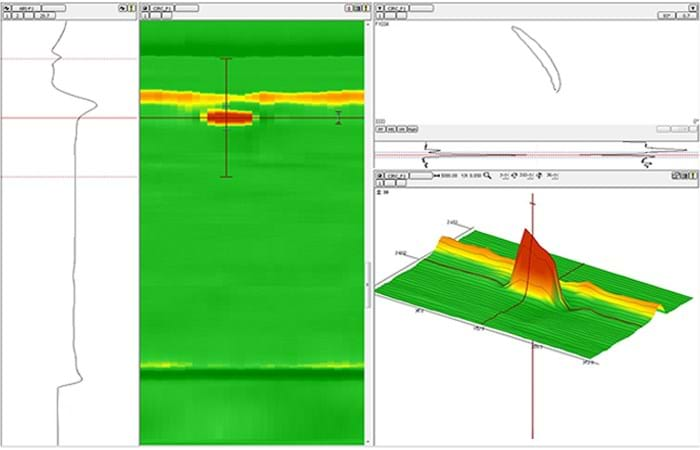

ECT is typically an adequate NDT method to detect small surface cracks and voids or cavities on tube surfaces. And advanced form of ECT called Eddy Current Array (ECA) has the additional benefits of covering a larger area in a single pass and/or providing an improved resolution, while providing clear 2D/3D images of the part being tested when required. The Eddyfi Ectane® is our solution for ECT and ECA examinations of tubes. The compact instrument is extremely reliable and capable of driving the right surface eddy current probes to perform the inspection.

These systems are developed for the production environment where productivity and reliability are key factors. Widely used by integrators proposing complete solutions to customers, these systems offer high speed and high-resolution inspection performance. Combined with an easy to use Software Development Kit (SDK), these systems are above all the perfect candidates for anyone developing an integrated inspection solution for tubes.

Visit our heat exchanger tube applications section to learn more about this specific application.