Tangential Eddy Current Array (TECA™)

Details

Tangential eddy current array (TECA) is an advanced electromagnetic inspection technology that uses ECA to introduce alternating currents into the surface of the component under test to detect and size surface-breaking cracks.

Just as with other eddy current techniques, cracks disturb the eddy current field generated by TECA and the return signal is instantaneously detected and sized. Probe operators are alerted on the spot of the presence of defects and their gravity. TECA also benefits from data recording and report generation, which are major advantages over alternative NDT methods.

Results from independent testing show that TECA exhibits better overall performances than magnetic particle testing (MT). TECA’s probability of detection (PoD) is significantly higher and the probability of making false calls much lower.

Ask an Expert

How Does TECA Work?

TECA is the perfect blend of multiplexed tangential coils and pancake coils. This advanced topology eliminates the need for multiple or raster scans, as it allows scanning wide surfaces in a single pass, which drastically reduces the time necessary to perform inspections. Tangential coils are positioned on their sides, their central axes parallel to the surface. The word tangential hints at the fact that eddy currents flow parallel to the surface and “dive” under cracks to measure their depth.

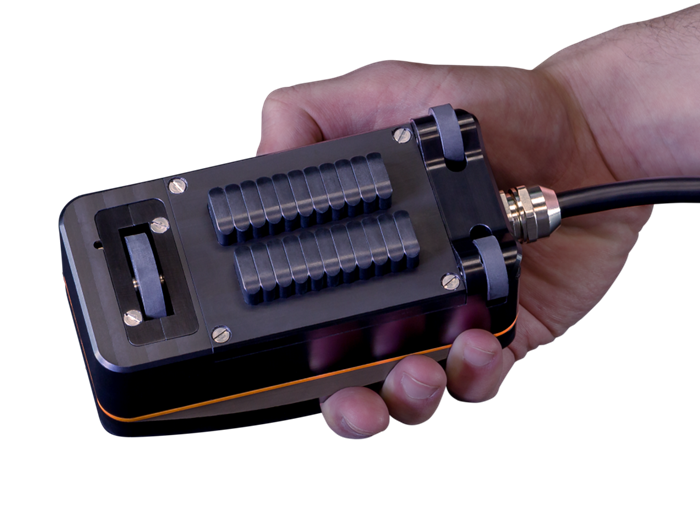

The Sharck™ probe is the current embodiment of TECA, applied to carbon steel welds.

Each finger in Sharck probes contains three coils: two tangential coils (working in a transmit-receive mode) and one conventional pancake coil used to monitor crack position and detect transverse cracks. Using several small coil arrangements yields great resolution, while multiplexing channels over many fingers provides a large, uniform eddy current distribution for optimal sensitivity.

While tangential eddy current is not an entirely new concept, it has never before been used in an array technique with high-performance multiplexing. One of TECA’s key advantages is that it offers signals similar to traditional ECT pencil probe signals, making TECA easy to learn, minimizing the ramp-up time, while being a more information-rich technique.

TECA Information

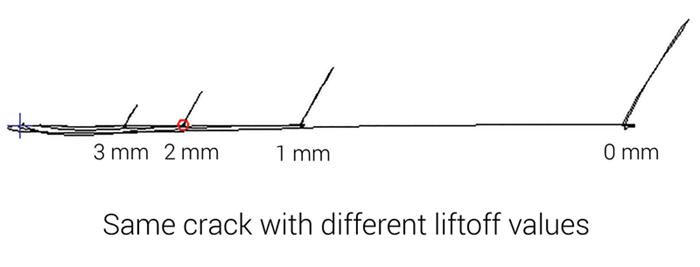

- An almost flat liftoff signal

- Crack-like indications approximately 90° relative to the liftoff signal

- All crack-like indications feature the same phase shift

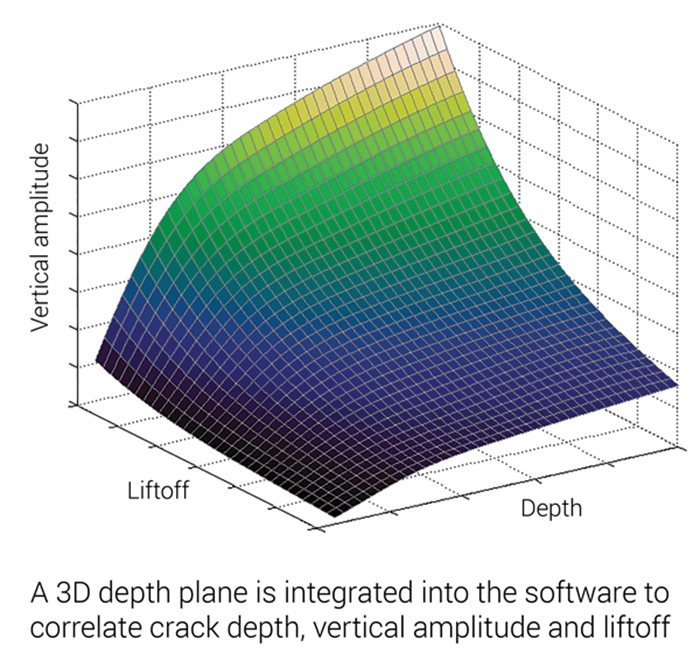

This has several major benefits, one being the capability of monitoring liftoff — unlike orthogonal coils that simply cancel the liftoff signal.

Obviously, the vertical amplitude of a given indication is impacted by liftoff. But thanks to a coil design capable of monitoring liftoff, the Sharck probe can compensate, offering accurate depth measurements.

Technology Feature Comparison Chart

Learn more