If predictive data-driven precision resonates with you, welcome to Eddyfi Technologies' Beyond Current experience featuring Permanently Installed Monitoring Systems (PIMS). These pioneering sensors secure the competitive edge for industries including oil & gas, mining, and power generation. PIMS perform non-intrusive routine health assessments to better help manage corrosion and erosion. By seamlessly integrating cutting-edge solid-state electronics and cloud-based software, they empower well-informed decision-making. With an AWS-hosted cloud system ensuring uninterrupted asset integrity monitoring, traditional manual inspections are obsolete. PIMS consistently deliver superior data for comprehensive analysis and proactive strategies.

Details

microPIMS Non-Intrusive Ultrasonic Sensors for Corrosion/Erosion Monitoring

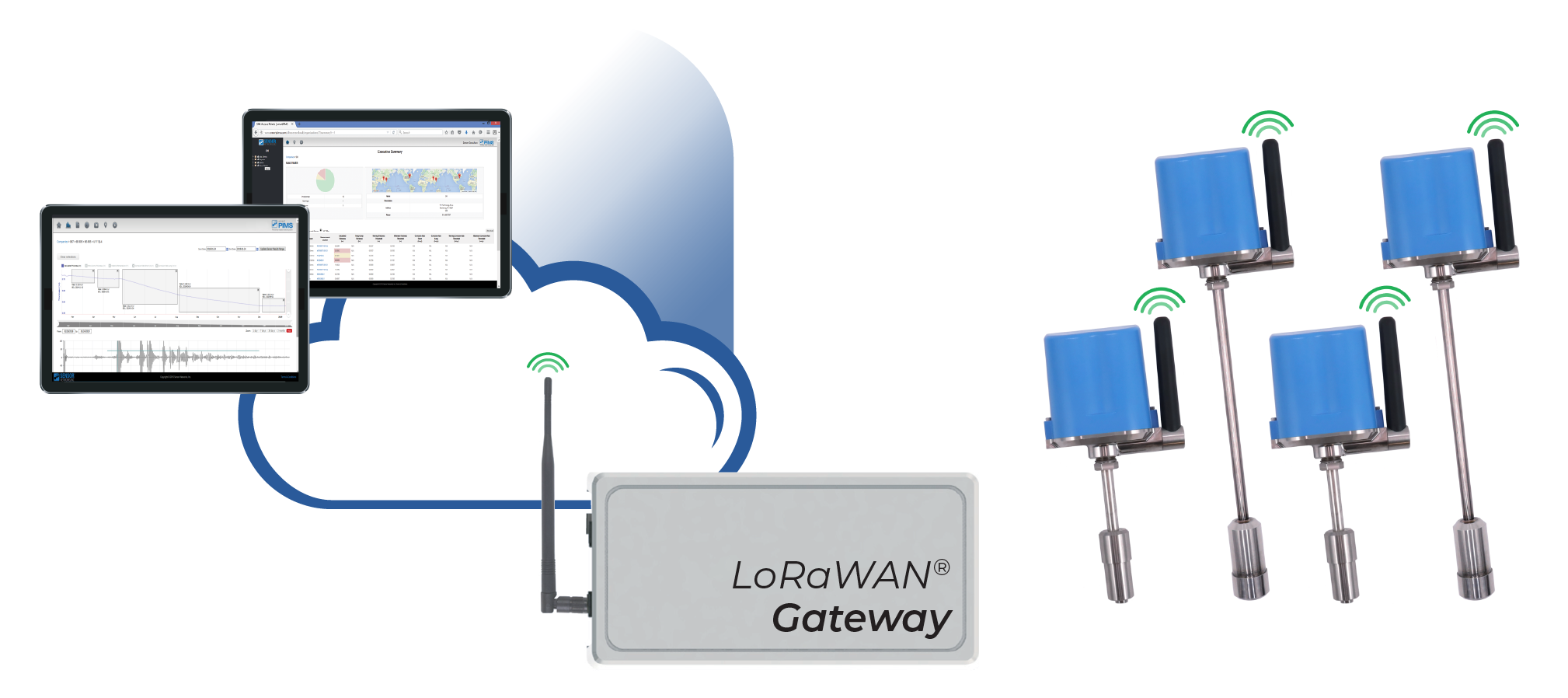

Experience the cutting-edge technology of microPIMS®, an intrinsically safe system by Eddyfi Technologies, leveraging acquired expertise in non-invasive corrosion monitoring. This state-of-the-art, fully wireless microPIMS system is ATEX Zone 0 Haz-Loc certified, powered by long-lasting batteries, and operates through long-range sub-Gigahertz wireless connectivity. Each microPIMS sensor is customizable to capture readings at user-defined intervals and seamlessly transmits data to webPIMS™, a cloud-based analysis portal for comprehensive insights and trends.

Key features:

- Long-Range Wireless Connectivity: Covering over a mile in ideal conditions with a star network topology that eliminates the need for repeaters.

- Extended Battery Life: Collect thickness data for up to 15 years with a single commercial, off-the-shelf battery, even at a daily reading frequency.

- Over-the-Air Flexibility: Seamlessly connect up to 1,000 microPIMS sensors per gateway, with a range extending up to approximately 1 mile, enabling adaptable monitoring setups.

- Cost-Efficient Solution: Minimize expenses associated with scaffolding and insulation removal/refitting for internal corrosion monitoring. The system offers more accurate and reliable data, enhancing operational efficiency and reducing installation costs relative to market standards.

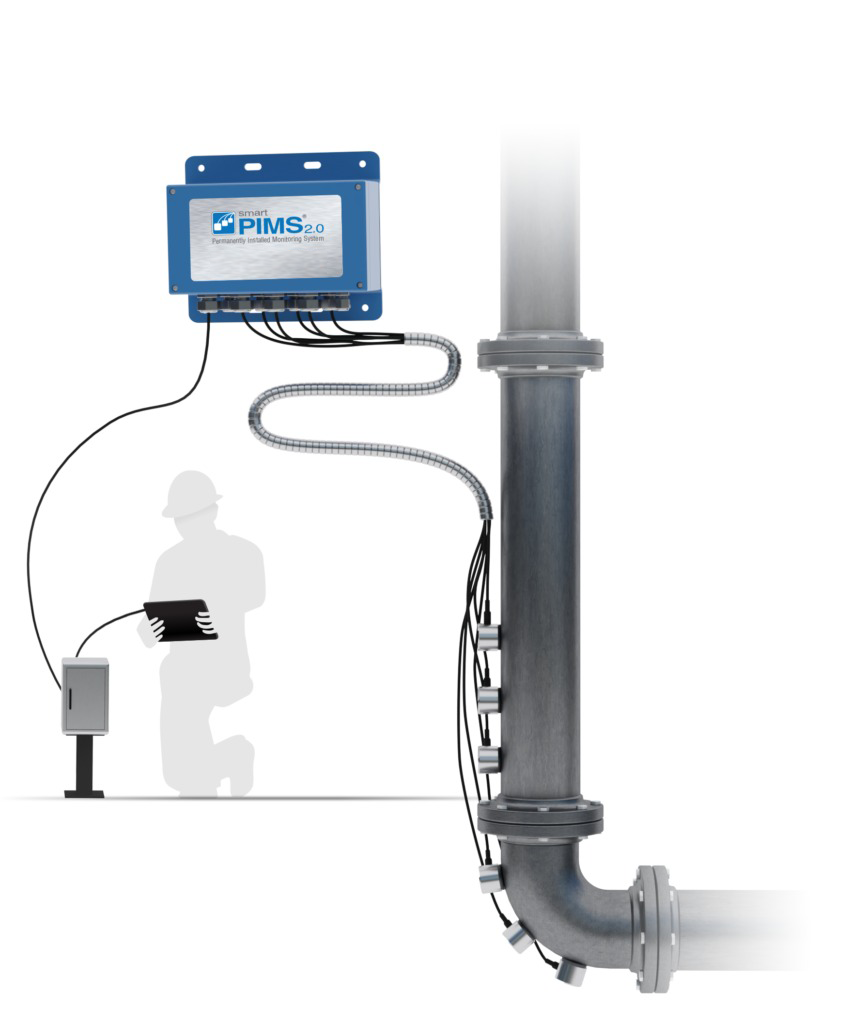

SmartPIMS® for Ultrasonic Corrosion/Erosion Monitoring

Modbus

smartPIMS Modbus is an advanced system that directly connects to your PC or laptop, enabling isolated measurements or seamless integration with your SCADA/DCS system. With customizable polling intervals, the collected data can be transmitted effortlessly to webPIMS for cloud-based analysis or exported to XML/CSV for reporting purposes.

Datalogger

The smartPIMS Datalogger system comes equipped with an onboard battery and memory for storing up to 3,000 thickness readings. It offers flexibility in capturing measurements at user-defined intervals, allowing for manual offloading to tablets or PCs via an RS-485 cable for analysis and tracking.

Cellular

Utilizing battery power and an integrated SIM card with a cellular radio, smartPIMS Cellular offers a cutting-edge solution. The Digital Sensor Interface (DSI) unit collects thickness measurements at customizable intervals, transmitting the data directly to webPIMS. These diverse connectivity options are engineered to cater to varied application needs, allowing multi-point monitoring with up to 16 ultrasonic sensors. This configuration enhances coverage of critical and problematic areas. The collected data can be seamlessly managed through manual or cellular transmission to the webPIMS software for database management, trend analysis, and comprehensive reporting.

Key features:

- Multi-Point Monitoring: Supports 16 single- or 8 dual-element UT sensor channels per DSI, ensuring comprehensive coverage.

- Direct Connectivity: Easily connects to computers or tablets for efficient data collection.

- High Precision: Maintains 1mil (0.025mm/0.001in) accuracy and detects minimum wall thicknesses of 1mm (0.040in).

- Flexible Installation: Suitable for above or underground use, with options for temporary or permanent setup.

- Ample Onboard Storage: Stores up to 3,000 readings with time, date, and waveform information for comprehensive data retention.

- Extended Battery Life: Collects thickness data for 1-2 years with just one daily reading, ensuring prolonged monitoring.

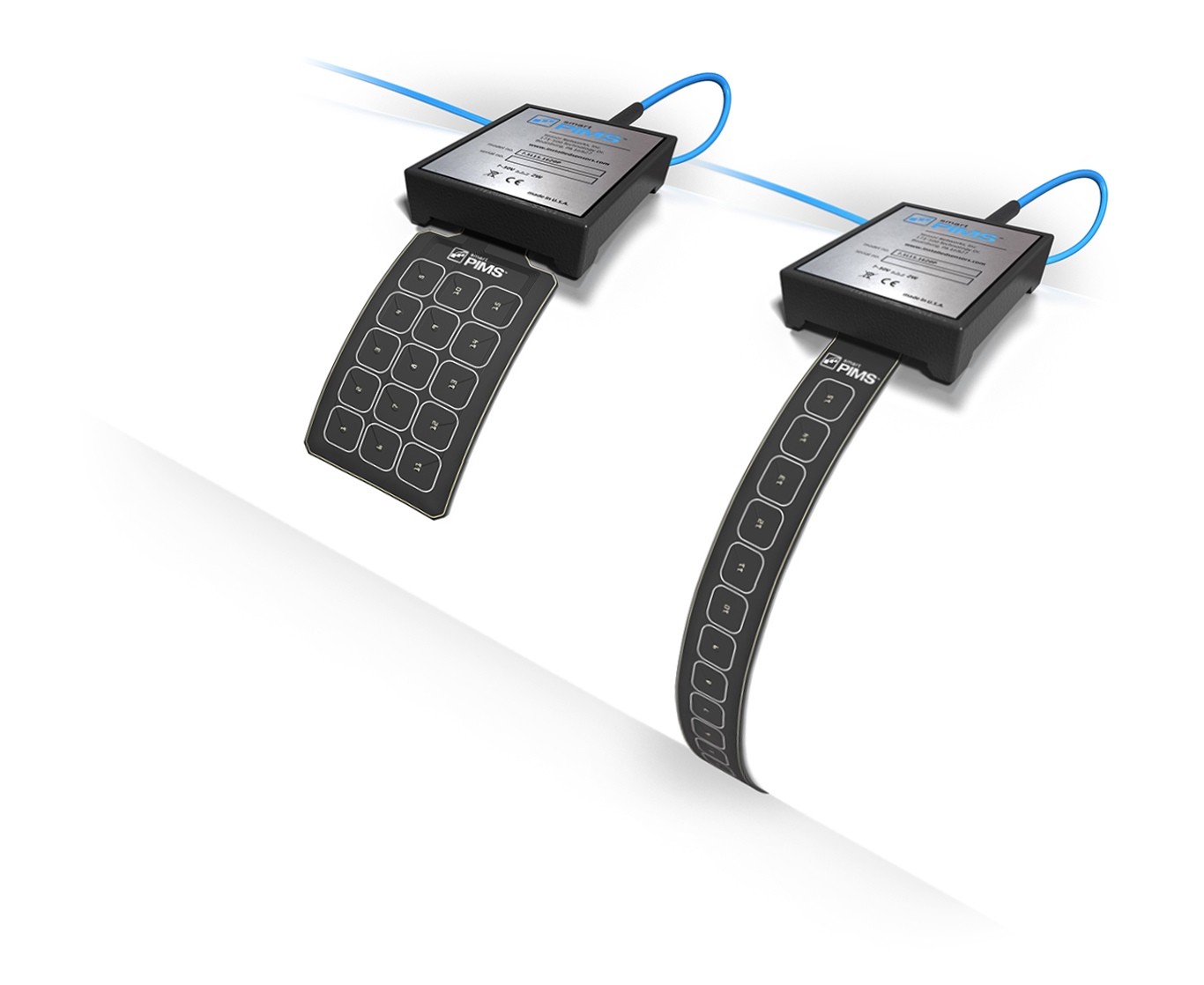

matPIMS Area Monitoring

matPIMS is an advanced non-intrusive corrosion monitoring system designed to collect thickness data over a surface area. It utilizes a sensor array that seamlessly transmits data for analysis to webPIMS or a SCADA/DCS system via Modbus (RS-485), providing frequent polling. Alternatively, measurements can be taken manually using a PC, laptop, or tablet. Available in two variations (3x5 and 1x15), matPIMS units feature single-element ultrasonic sensors arranged in an array/matrix pattern, ensuring consistent coverage of critical or targeted areas.

Key features:

- Area Monitoring Capability: Equipped with 15 single-element UT sensor channels per matPIMS unit, ensuring comprehensive area coverage for precise monitoring.

- Cost Efficiency: Reduces expenses related to manual thickness readings, enhancing operational efficiency with more accurate and reliable data.

- High Precision Resolution: Maintains a remarkable precision of 1mil (0.025mm/0.001in) and can detect minimum wall thicknesses of 1mm (0.040in), ensuring detailed and accurate measurements.

- Quick & Versatile Installation: Suitable for both above and underground installations, ensuring flexibility and ease of setup.

microTEMP Rugged, Wireless, Non-Intrusive Temperature Sensors

In petrochemical and downstream oil & gas operations, maintaining precise temperatures is crucial. The microTEMP Intrinsically Safe sensor offers wireless, non-intrusive temperature monitoring for hazardous Zero 0 locations, ensuring operational enhancement while meeting safety and quality standards.

Eddyfi Technologies' microTEMP provides real-time temperature measurement using a robust, long-life battery and long-range LoRaWAN connectivity. It transmits data to the private webPIMS system for analysis and storage and alerts users via email or SMS about temperature deviations beyond set limits.

Key features:

- Single-Point Monitoring: Connect up to 1,000 microTEMP sensors per gateway within a range of up to 1.6km (~1mi), offering comprehensive coverage.

- Continuous Temperature Monitoring: Detects temperatures from -40°C (-40°F) up to 600°C (1,112°F) swiftly, ensuring quick response to temperature changes.

- Real-Time Alerts: Receive immediate alerts via email and SMS if temperatures exceed predefined ranges, ensuring prompt action to safeguard assets.

- Easy Installation & Integration: Cost-effective and non-intrusive, microTEMP integrates seamlessly into new or existing LoRaWAN networks, offering a more efficient solution compared to wired thermocouples.

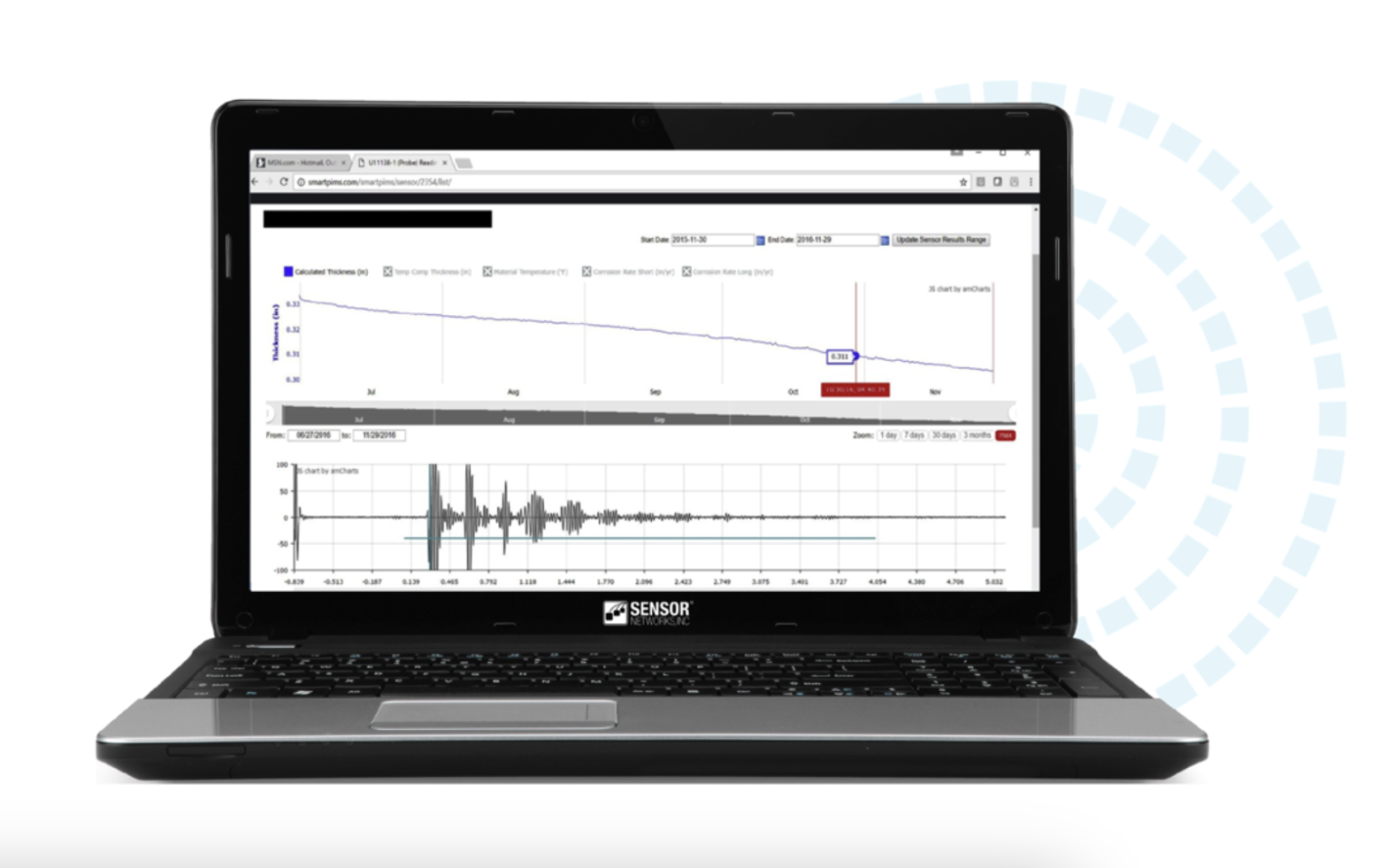

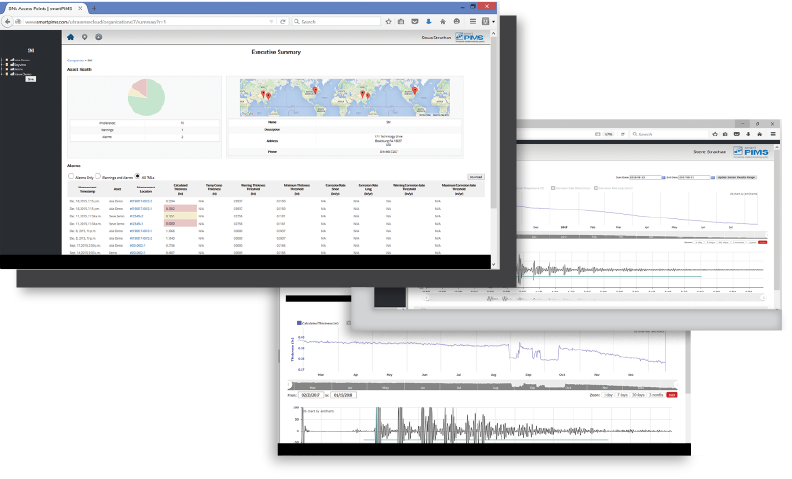

webPIMS Software for Continuous Access to Additional and Improved Data

Eddyfi Technologies’ webPIMS cloud-based, back-end corrosion/erosion data management software allows users to quickly and easily analyze, set alarms for, trend, map, export, and report metal-loss data rates. webPIMS can automatically or manually receive data from ultrasonic sensors for web-based display, storage, trending, and analysis. Users can access this data from anywhere with an internet-enabled device such as a PC, tablet, or smartphone.

Use webPIMS for:

- Custom Alarms: Set personalized alerts based on corrosion rate thickness to keep informed proactively.

- Trending Analysis: Compare historical data with operating schedules to optimize process control effectively.

- Temperature Compensation: Ensures consistent and accurate thickness data by automatically adjusting thickness readings based on measured process temperatures.

- On-Premises Solution: For data security, On-Prem webPIMS offers a local, self-contained system within the facility's boundaries.

- Efficient Data Export: Easily export data to XML or CSV for reporting or to integrate with historians/IDMS.

- Customization: Add location images, descriptions, and notes to specify sensor placement and other crucial details.

Benefits

Data Fidelity & Integrity

Installed sensors ensure superior quantity and quality of measurement data. They provide precise traceability of date, time, location, temperature, and RF waveform signals for enhanced data accuracy.

Safety

Non-intrusive UT sensors, whether permanent or temporary, enable data collection without manual inspection, ensuring personnel safety by avoiding work in hazardous ATEX Zone 0 areas.

Data Privacy

Eddyfi Technologies' non-intrusive monitoring systems seamlessly integrate into private networks and backend systems, offering heightened security. Wired systems directly connect to PCs or Modbus networks, safeguarding critical data.

Superior Measurement

Our dual-element UT corrosion sensors set an industry standard, measuring down to 1mm (0.040in). The ultra-high-temp model includes temperature for precise compensation calculations, ensuring unparalleled measurement accuracy.

Specifications

microPIMS Sensors

Dual Element: Dual

Ultra-High Temp: Single (Delay Line)

Dual Element: 5 MHz

Ultra-High Temp: 7 MHz

Dual Element: 0.375” (10mm)

Ultra-High Temp: 0.375” (10mm)

Dual Element: 0.040-4” (1-100mm)

Ultra-High Temp: 0.125-1” (3-25mm)

Dual Element: -40 to +275°F (-40 to +135°C)

Ultra-High Temp: -40 to +932°F (-40 to +500°C)

Dual Element: 20.5 oz (580g)

Ultra-High Temp: 31 oz (880g)

Dual Element: 9.5 x2 .8” (241 x 70mm)

Ultra-High Temp: 15.5 x 2.8” (394 x 70mm)

smartPIMS Sensors

XD-301 (Dual Element): Sever Pitting

XD-201 (Delay Line): Ultra-High Temp

Temperature Sensor: N/A

XD-301 (Dual Element): 5 MHz

XD-201 (Delay Line): 7 MHz

Temperature Sensor: N/A

XD-301 (Dual Element): 0.375” (10mm)

XD-201 (Delay Line): 0.375” (10mm)

Temperature Sensor: N/A

XD-301 (Dual Element): 0.75 x 0.75” (19 x 19mm)

XD-201 (Delay Line): 0.8 x 2.25” (20.3 x 57.2mm)

Temperature Sensor: 0.062 x 18” (1.57 x 457.2mm)

XD-301 (Dual Element): 1-8

XD-201 (Delay Line): 1-16

Temperature Sensor: N/A

XD-301 (Dual Element): 0.001” (0.025mm)

XD-201 (Delay Line): 0.001” (0.025mm)

Temperature Sensor: N/A

XD-301 (Dual Element): 0.040-4.0” (1-100mm)

XD-201 (Delay Line): 0.125-1.0” (3-25mm)

Temperature Sensor: N/A

XD-301 (Dual Element): -40 to +275°F (-40 to +132°C)

XD-201 (Delay Line): -40 to +932°F (-40 to +500°C)

Temperature Sensor: -40 to +932°F (-40 to +500°C)

XD-301 (Dual Element): Magnet/Adhesive or Temporary

XD-201 (Delay Line): Mechanical Clamp/Gold Foil

Temperature Sensor: N/A

matPIMS Sensors

M-PIMS115: General Wall Loss

M-PIMS35: General Wall Loss

Custom: General Wall Loss

M-PIMS115: 7.5 MHz

M-PIMS35: 7.5 MHz

Custom: 7.5 MHz

M-PIMS115: 0.25” (6.35mm)

M-PIMS35: 0.25” (6.35mm)

Custom: 0.25” (6.35mm)

M-PIMS115: 1.0 x 9.12” (25.4 x 231.6 mm)

M-PIMS35: 2.0 x 2.7” (50 x 68mm)

Custom: 1 x up to 100” (25.4 x up to 2540mm)

M-PIMS115: 16 (15 active, 1 ref.)

M-PIMS35: 16 (15 active, 1 ref.)

Custom: Up to 32

M-PIMS115: 0.001” (0.025mm)

M-PIMS35: 0.001” (0.025mm)

Custom: 0.001” (0.025mm)

M-PIMS115: 0.125-6.0” (3-150mm)

M-PIMS35: 0.125-6.0” (3.0-150mm)

Custom: 0.125-6.0” (3.0-150mm)

M-PIMS115: -5 to +150°F (-20 to +65°C)

M-PIMS35: -5 to +150°F (-20 to +65°C)

Custom: -5 to +150°F (-20 to +65°C)

M-PIMS115: Epoxy

M-PIMS35: Epoxy

Custom: Epoxy